Steel CNC Machining Services & Machined Parts – Carbon Steel Machining Company

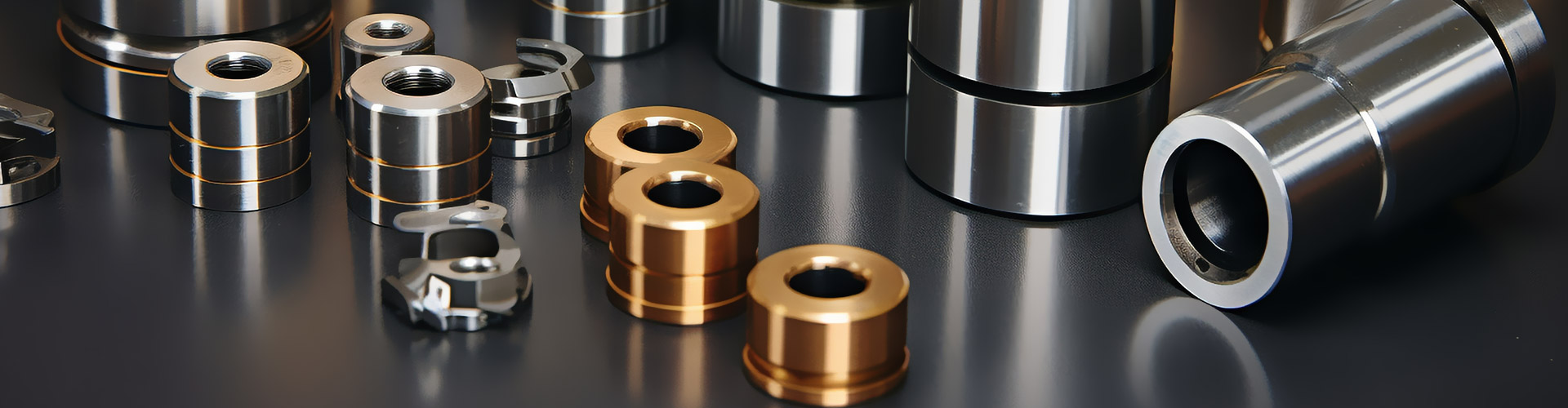

Working with professional and experienced manufacturers can help you save time and money, and Biyou is one of them. Based on decades of experience in steel CNC machining services, our engineers, designers and technicians have the ability to optimize product design, prototype building, material selection and steel part production. We also have a fully equipped machine shop and advanced manufacturing facilities that can provide custom CNC machined steel parts with simple or complex geometries, applying a variety of techniques including milling, turning, drilling, wire EDM, grinding or other machining Craftsmanship as well as finishing services and more manufacturing methods. Biyou is your best choice, welcome to send us your inquiry. We can produce machined steel parts and components made from different types of carbon steel alloys, mild steel, etc.

CNC Machining In Steel – Steel Properties And Benefits

Steel is the backbone material of general engineering and industrial applications and is widely used in CNC machining, especially the low-carbon and medium-carbon steels. Steel is an alloy of iron and carbon usually contains many other elements such as manganese, silicon, phosphorus, and oxygen. The carbon content in steel improves its strength and fracture resistance. Most steels have good machinability and weldability, and can be well heat treated. Steel tends to be the first option for sectors like automotive, aerospace, and applications where require high durability and performance, and CNC machining is often the manufacturing method for these industries. In terms of its benefits and advantages, steel is much stronger than many other materials and very affordable at the same time.

Why Choose Steel CNC Machining Services At Biyou

• Quality certifications allow us to export steel and metal CNC products worldwide

• Up-to-date equipment and machinery and trained workers ensure the productivity

• Over 10 years of experience in machining in different industries and markets

• Great location condition helps the transportation of the goods and for faster delivery

Steel is a commonly used metal. Steel is the backbone material for general engineering and industrial applications. It is widely used in CNC machining, especially low carbon and medium carbon steel. Due to its high strength and corrosion resistance, it is widely used in manufacturing industries1. CNC machining is a high-precision machining method that produces high-quality parts2. The advantages of CNC machined steel include: ease of cutting or shaping, strong corrosion resistance and wear resistance, which will extend the life and service life of the part.

What types of steel are most commonly used in CNC manufacturing? Mild and low carbon steels are widely used to produce high-volume CNC parts due to their good machinability and favorable cost, while medium carbon steels have balanced strength and ductility, combined with their advantages in wear resistance and other mechanical properties make it ideal for large CNC steel parts in automobiles. Below are the different processed steels and their characteristics. We use a variety of steel alloys, not limited to the following alloys.

1. 45# steel: often used to manufacture mechanical parts, bearings, gears, etc.

2. 20# steel: often used to manufacture mechanical parts, bearings, gears, etc.

3. 40Cr steel: often used to manufacture high-strength bolts, bearings, gears, etc.

4. 35CrMo steel: often used to manufacture high-strength bolts, bearings, gears, etc.

5. 42CrMo steel: often used to manufacture high-strength bolts, bearings, gears, etc.

6. 65Mn steel: often used to make springs, knives, saw blades, etc.

7. 20CrMnTi steel: often used to manufacture gears, bearings, etc.

8. 30CrMnTi steel: often used to manufacture gears, bearings, etc.

These steel alloys have good processing and mechanical properties in CNC machining and are suitable for the processing and manufacturing of various mechanical parts.