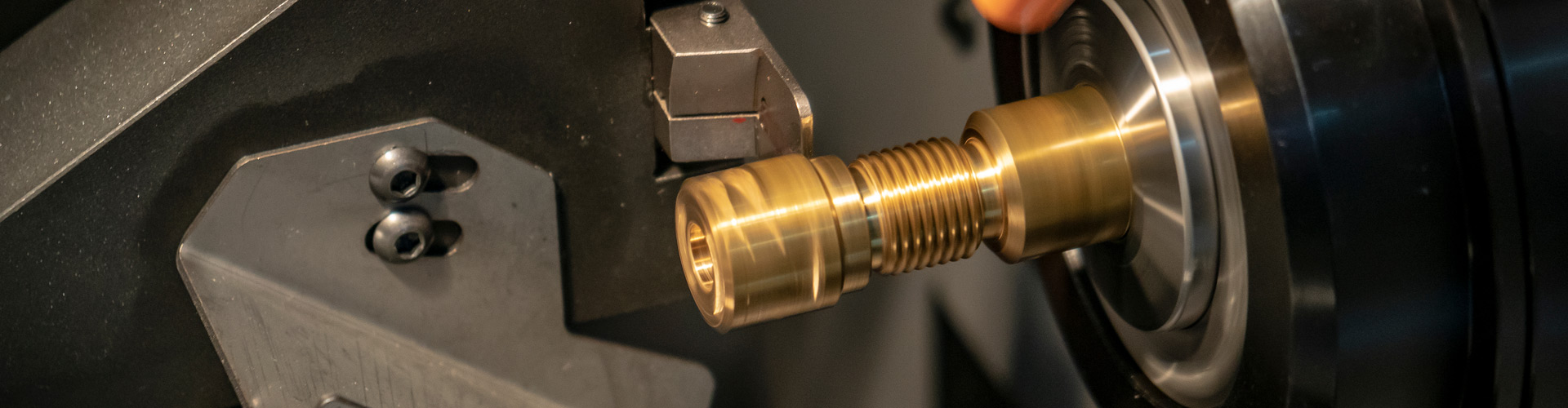

CNC Machining Brass Parts

Brass is an alloy whose main components are copper and zinc. It has good processing properties, good ductility and corrosion resistance, and is often used to manufacture mechanical parts, pipes, valves, clocks and musical instruments, etc. The color of brass is golden yellow, hence its name. It also has good electrical and thermal conductivity. Brass parts are often used in mechanical equipment, electronic products, automobile parts and other fields. Therefore, CNC processing of brass parts has broad application prospects in industrial production.

Features & Advantages Of Custom Machining Brass CNC Parts

Brass parts and components provide a tighter seal for fittings

– Can reduce production costs and is very strong under high stress

– Can withstand extreme temperatures

– Easy to cast

– Heat-resistant, corrosion-resistant, rust-proof and with better performance

– Extremely durable and long lasting

Applications:

1. Valves and pipe fittings: Brass has good corrosion resistance and thermal conductivity, making it suitable for manufacturing valves and pipe fittings.

2. Electrical connectors: Brass has good electrical conductivity and processability, and is suitable for manufacturing electrical connectors and sockets.

3. Mechanical parts: Brass has certain strength and wear resistance, and is suitable for manufacturing mechanical parts, such as bearings, gears, etc.

4. Decoration and household items: Brass has good toughness and decorative properties, and is suitable for making decorations and household items, such as door handles, lamps, etc.

In general, brass is suitable for manufacturing parts and products that require corrosion resistance, thermal conductivity, electrical conductivity, and a certain degree of strength.