CNC Machining In PEEK – What Is PEEK Plastic?

PEEK plastic is a semi-crystalline, thermoplastic special engineering plastic, and its Chinese name is polyetheretherketone. PEEK plastic has excellent comprehensive properties such as high temperature resistance, self-lubrication, corrosion resistance, flame retardancy, hydrolysis resistance, wear resistance and fatigue resistance. PEEK plastic was initially used in the national defense and military industries, and then gradually expanded to civilian fields, including industrial manufacturing, aerospace, automotive industry, electronic and electrical, and medical equipment. PEEK plastic is suitable for various processing methods such as injection molding, extrusion molding, compression molding and melt spinning. In recent years, the combination of PEEK resin with advanced manufacturing technologies such as 3D printing has given it a new development direction in medical fields such as medical implants.

Benefits Of PEEK Plastic

High temperature resistance

Corrosion resistance

Good wear resistance

Has high strength and rigidity

Good fatigue resistance

Low hygroscopicity

Biocompatibility (medical grade)

Lightweight alternative to most soft metals

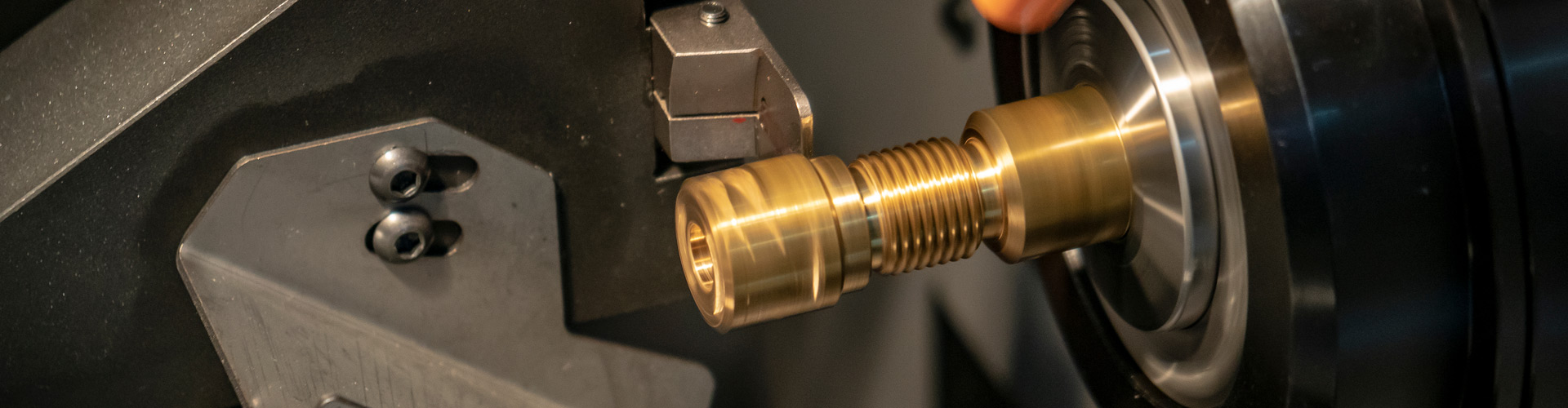

PEEK CNC Machining Services – PEEK Plastic Machining Parts Manufacturer

Biyou has many years of plastic CNC processing experience and can process various plastic materials and PEEK grades. As China's leading plastics and composites processing company, we can employ multi-axis CNC PEEK machining to ensure efficiency and precision for even the most complex geometries and tight tolerance requirements. CNC machined PEEK parts are manufactured according to customer requirements or submitted CAD drawings, and our engineers and designers will help you refine your model to get the best results and reduce costs. If you would like to develop a project regarding PEEK (polyetheretherketone) products or prototypes, we would be happy to discuss all the details with you. Consistent communication will also be maintained throughout the production cycle of PEEK machined parts. PEEK CNC machining services are primarily about reducing manufacturing errors and increasing productivity while delivering superior quality and precision.

Common applications and uses of CNC PEEK machined parts include:

1. Medical devices: PEEK material has excellent biocompatibility and high temperature resistance, so it is often used to manufacture medical device parts, such as orthopedic implants, artificial joints, surgical tools, etc.

2. Aerospace: PEEK material has the characteristics of lightweight, high temperature resistance, corrosion resistance, etc., and is suitable for parts manufacturing in the aerospace field, such as aircraft engine parts, spacecraft parts, etc.

3. Automotive industry: PEEK material has excellent wear resistance and chemical stability, and is suitable for parts manufacturing in the automotive industry, such as engine parts, transmission system parts, etc.

4. Electronic communications: PEEK material has excellent insulation properties and high temperature resistance, and is suitable for manufacturing parts of electronic communications equipment, such as connectors, insulation parts, etc.

5. Chemical industry: PEEK material has the characteristics of high temperature resistance and corrosion resistance, and is suitable for the manufacturing of parts in the chemical industry, such as pumps, valves, pipelines, etc.

In general, CNC PEEK processed parts are widely used in various fields, and are mainly used to manufacture parts that require high temperature, wear resistance, corrosion resistance and other properties.