CNC Machining In PTFE/Teflon – What Is PTFE Plastic?

Polytetrafluoroethylene (Teflon or PTFE), commonly known as the "King of Plastics", is a polymer compound polymerized from tetrafluoroethylene. It has excellent chemical stability, corrosion resistance, air tightness, high lubricity, non-stick and electrical conductivity. Good insulation and aging resistance. Used as engineering plastics, it can be made into PTFE tubes, rods, strips, plates, films, etc. Generally used in corrosion-resistant pipelines, containers, pumps, valves, radars, high-frequency communication equipment, radio equipment, etc. PTFE is also used in medical applications, such as artificial blood vessels, heart valves, etc.

Benefits Of PTFE Plastic

● High-temperature resistance: operating temperature up to 250 ℃.

● Low-temperature resistance: retain the elongation of 5% even if the temperature drops to – 196 ℃.

● Corrosion resistance: resistant to strong acids, alkalis, water, and various organic solvents.

● Weather resistance: best aging life of plastics.

● High lubrication: the lowest friction coefficient among solid materials.

● Non-adhesion: does not adhere to any substance.

● No toxicity: can be implanted into the body as artificial blood vessels and organs for a long time without adverse reactions.

Properties And Applications Of Machined Teflon/PTFE

Polytetrafluoroethylene (PTFE) is a polymer material with excellent chemical stability and wear resistance. It is often used for machining into various parts and seals. PTFE has the following properties and applications:

Performance:

1. High temperature resistance It has excellent high temperature resistance and can work stably in the temperature range of -200°C to 260°C.

2. Excellent chemical stability: It has good stability against most chemical substances and is not easily corroded.

3. Low friction coefficient: It has an extremely low friction coefficient, making it an ideal lubricating material.

4. Good insulation properties: It has excellent insulation properties and can be used to manufacture electrical insulation components.

Application:

1. Seals: Because of its excellent high temperature resistance and chemical stability, it is often used to manufacture various seals, such as sealing rings, gaskets, etc.

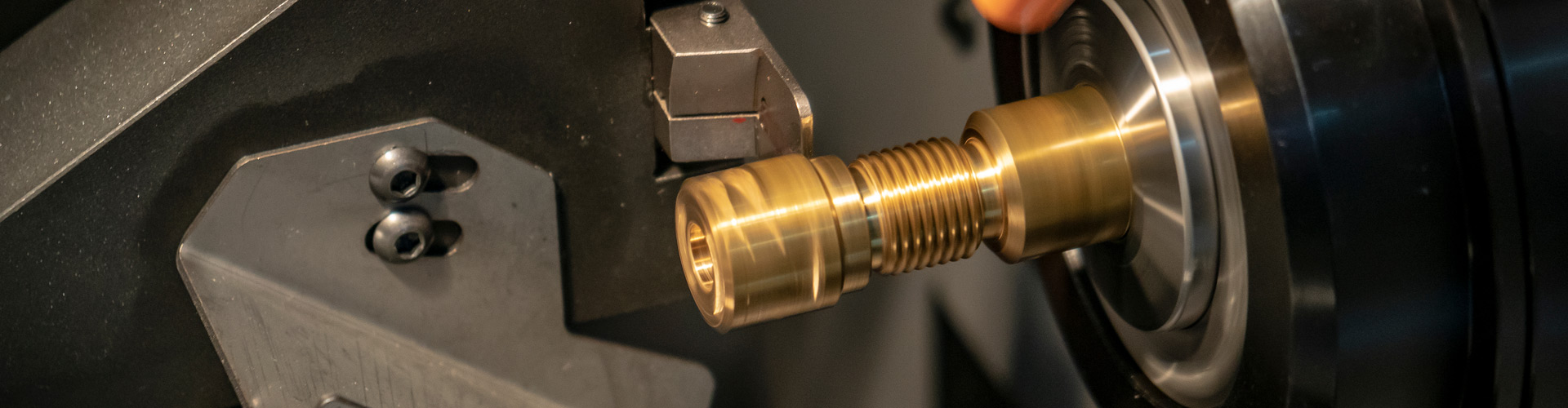

2. Valve parts: It can be used to manufacture valve parts, such as valve seats, valve stem seals, etc., to ensure the sealing performance and wear resistance of the valve.

3. Pump parts: It can be used to manufacture pump blades, pump bodies and other parts to improve the corrosion resistance and wear resistance of the pump.

4. Electrical insulation parts: Because of its good insulation properties, it is often used to manufacture electrical insulation parts, such as wire insulation sleeves, electrical connectors, etc.

In general, PTFE is widely used in machinery manufacturing, chemical industry, electronics and other fields due to its excellent properties, and has become an important engineering plastic material.

Why Choose Biyou CNC POM Machining Service?

● No quality and delivery issues

● Ability to deliver prototypes and high-volume production runs

● Meet industry standards

● Extensive machining and manufacturing technology

● Professional design enhancements and customization options