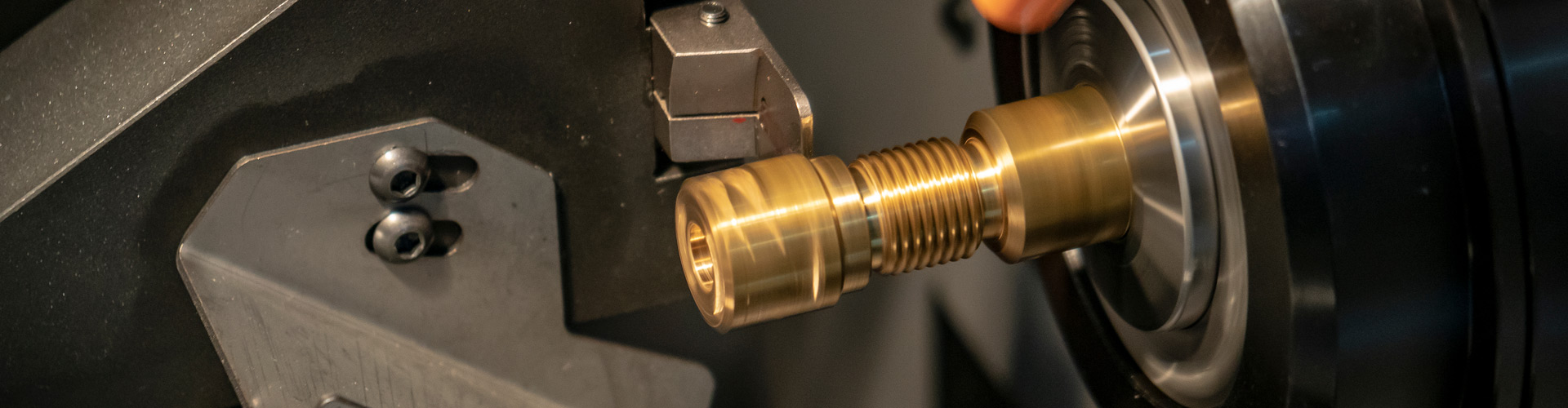

Copper CNC Machining Services

With rich experience, Biyou provides copper CNC machining services and machined components to various industries. A complete CNC manufacturing facility and a variety of machining capabilities allow us to manufacture copper parts of varying sizes, complexity, and specifications to meet or exceed customer expectations. With a fully equipped machine shop, our experienced technicians can perform CNC milling, turning, wire EDM, 5-axis machining and many more processes for creating prototype and end-use CNC copper parts. Our engineers will help you improve your design and reduce costs, and you can upload your CAD files for a free online quote. We also offer a variety of surface treatments for copper machined parts, such as electroplating and electropolishing.

Copper In CNC Machining – Copper Properties And Benefits

Copper is a common metal material that is widely used in CNC machining. Copper has many advantages and properties that make it one of the materials of choice in many manufacturing sectors.

1. Conductivity: Copper is an excellent conductive material, so it is often used in the manufacture of electronic components, circuit boards, wires and other products.

2. Thermal conductivity: Copper has excellent thermal conductivity and can effectively conduct heat, so it is often used to manufacture radiators and other products that require good thermal conductivity.

3. Corrosion resistance: Copper has good corrosion resistance and can resist the erosion of most chemicals, so it is suitable for manufacturing products with high corrosion resistance requirements.

4. Processing performance: Copper has good processing properties, is easy to cut and form, and is suitable for various CNC machining operations.

5. Good plasticity: Copper is a metal material with good plasticity and can be formed into various complex shapes through cold and hot processing.

6. Decoration: Copper has good decorative properties and is often used to make exquisite decorations and crafts.

In general, copper has excellent electrical conductivity, thermal conductivity, corrosion resistance and processing properties, is suitable for manufacturing various products, and performs well in CNC machining. Therefore, copper has a wide range of applications in manufacturing.

Characteristics And Uses Of Commonly Used Copper And Copper Alloys:

|

No. |

Characteristics | Application |

| 1. C10700 | Silver-containing oxygen-free copper has excellent cold and hot processing properties. | It is mainly used as automatic adjustment washers, radiators, radio parts, and printed circuit boards. |

| 2. C11000 | Both cold and hot processing properties are excellent. | Mainly used as building materials, automobile radiators, gaskets, radio parts |

| 3. C14500 | The rods made of it have excellent cutting performance and can be cut at high speed on automatic lathes. The cutting is not filamentous. This material also has high electrical conductivity, thermal conductivity and good corrosion resistance. | Mainly used for advanced electromechanical parts, castings and threaded cutting parts, plumbing fittings, electrical contacts, automotive parts, advanced welding and cutting nozzles, motors and switch components, etc. |

| 4.C17200 | It is a typical precipitation-strengthened copper alloy. In addition to high strength, elasticity, hardness, corrosion resistance, high and low temperature resistance, non-magnetic, and no sparks during impact, etc. | C17200 has very good processing performance and can be processed into complex shapes using various molding methods. |

| 5.C18200 | Chromium copper has good electrical conductivity, thermal conductivity, high hardness, wear resistance, explosion resistance, crack resistance and softening temperature. It has low electrode loss during welding, fast welding speed and low total welding cost. | Mainly used as resistance welding electrodes, electrical switches, circuit breaker parts, and high-intensity electric heating parts |

| 6.C20500 | Is a brass alloy containing large amounts of aluminum and manganese. It has good corrosion resistance and processability. | It is commonly used in the manufacture of electrical and electronic components such as plugs, sockets, terminals and connectors |

| 7.C26000 | It is a brass alloy mainly composed of copper, zinc and lead. It has high electrical and thermal conductivity, corrosion resistance, moderate strength and easy processing and formability. 12. C26000 brass has extremely excellent high temperature resistance and softening ability. | This alloy is often used to make cartridge cases, radiator fins, automobile parts, electrical parts, bathroom accessories, etc. |

| 8.C36000 | C36000 is a lead brass, as defined by American ASTM standards. Its chemical composition includes copper, lead, zinc and iron. It has good cutting performance and friction reducing performance, | Commonly used in watch parts, automobiles, tractors and general machine parts. |

| 9.C38500 | It has excellent cutting performance, wear resistance and high strength. | It is mainly used for building profiles, door and window frames, loose leaves, locks and forged parts, etc. |

| 10.C46400 | The mechanical properties of brass show its excellent strength and toughness, and it has good hot workability and hot forging capabilities. Better corrosion resistance in seawater. | It is usually used in seawater treatment equipment, submarine pipelines and other occasions, as well as joint parts on aircraft, small hardware, bolts and nuts on ships. |

| 11.C67300 | It has high electrical conductivity, thermal conductivity, corrosion resistance, moderate strength, easy processing and formability, and has better high temperature resistance and softening ability than pure copper. | Widely used in automobile water tanks, heat sinks, motor commutators, relays, etc.; |

| 12.C93200 | It has excellent processing performance, good hardness, strength and wear resistance, and excellent wear resistance. | It is often used in applications such as general purpose bearings and bushings. |